Suspension Ball joint links between the tire side (Hub Carrier) and Suspension arm, and allow the bouncing and steering movement of tires, in order to keep the tires always in the ideal position. Our bodies are made up of a lot of joints. The joints help us move more dynamically and flexibly, and this movement relieves the impact. The ball joint is like the joint of a vehicle suspension. Connect between control arm and knuckle.

Ball Joint Introduction

The cars suspension ball joint is the pivot point between the control arm and the spindle or steering knuckle. Usually a ball stud in socket design, lubricated with grease and covered with a dust boot. They are universally used in the front suspension, having replaced the kingpin arrangement. It can also be found in the rear suspension of a few higher performance vehicles. Ball joints play a critical role in the safe operation of an automobile’s steering and suspension.

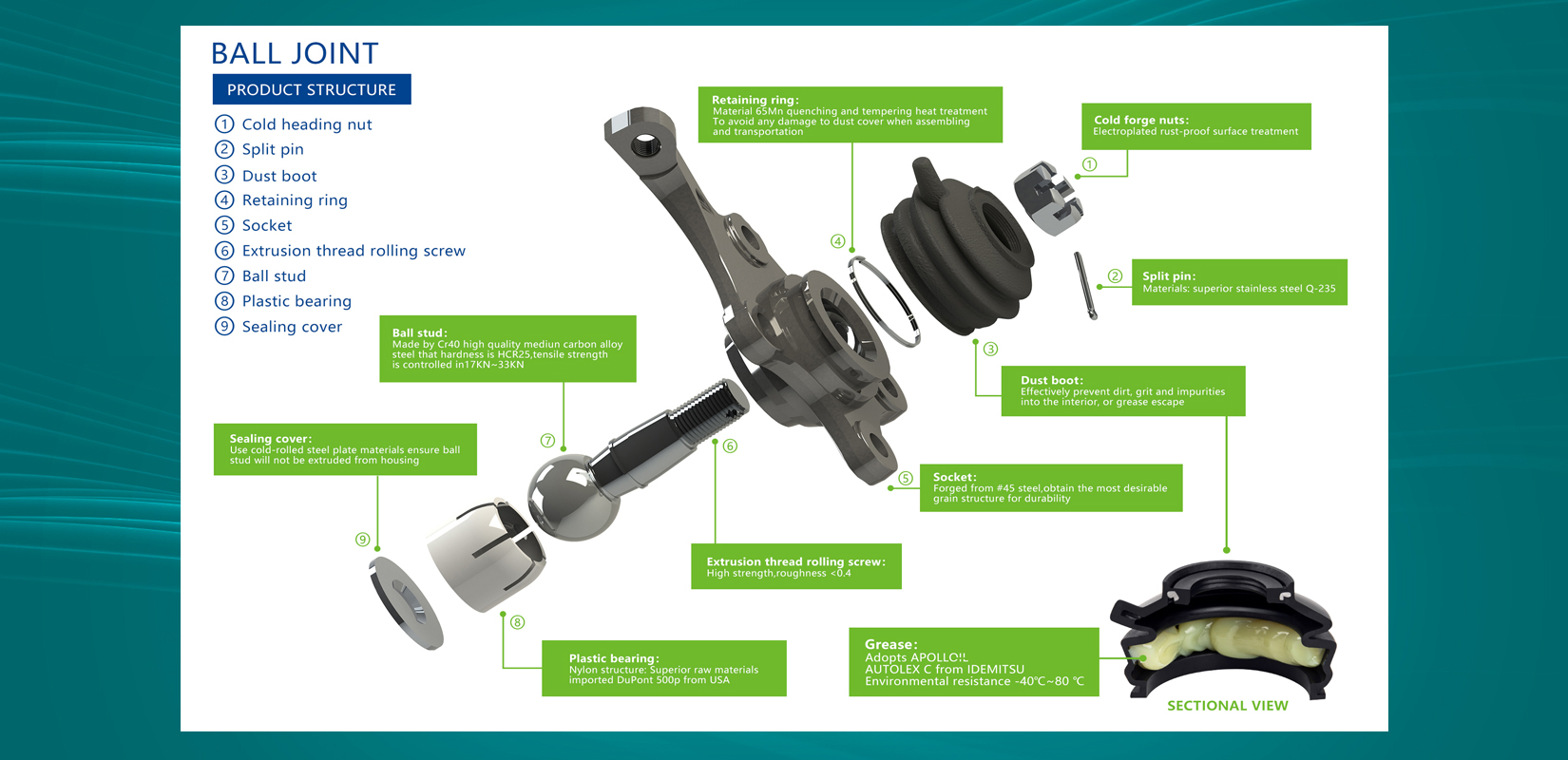

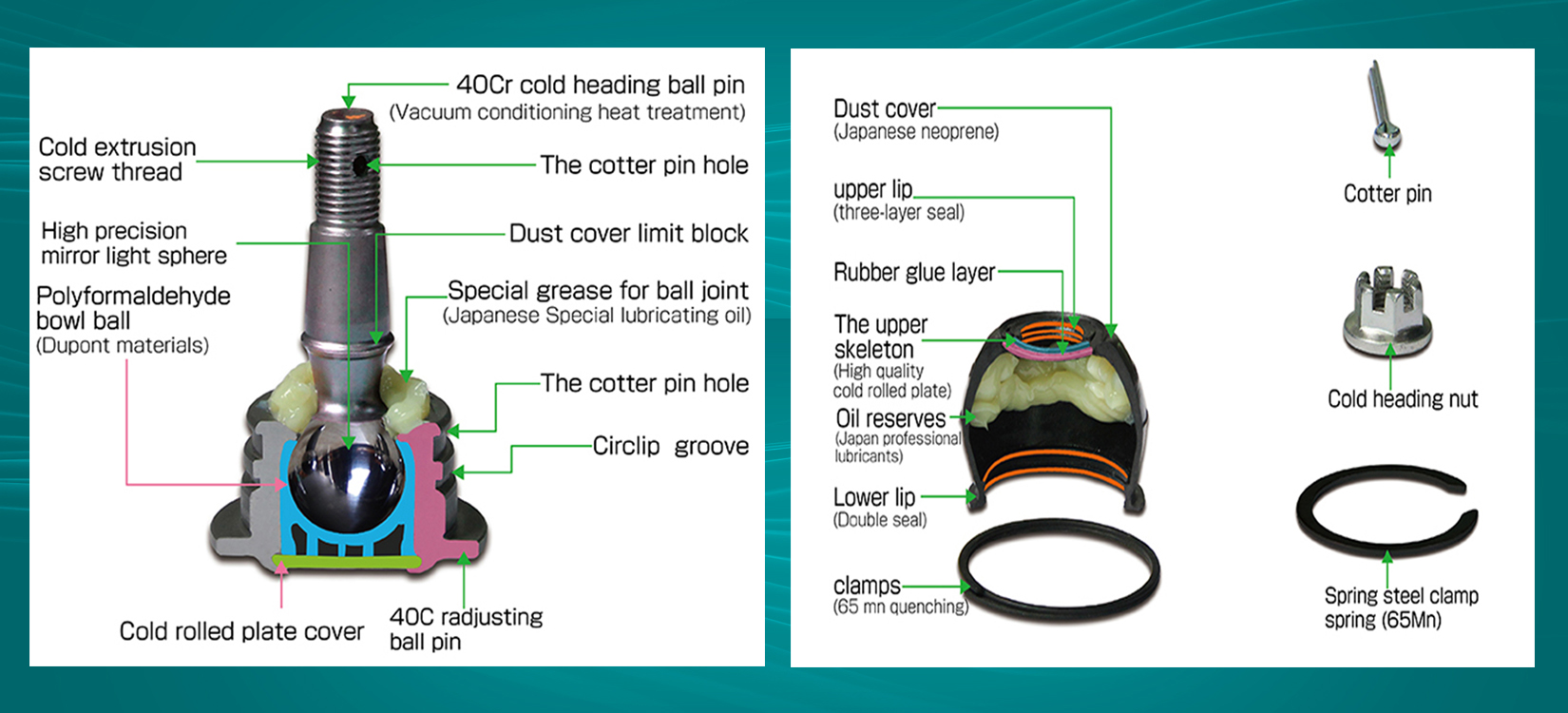

Ball joints consist of a metal housing and a stud that can swing and rotate within the housing. Bearings inside the housing are placed between the ball stud and housing to help reduce wear and friction. The socket is filled with grease to provide lubrication, keep debris and water out of the socket, and maintain noise free operation. A rubber boot, located at the opening of the joint, keeps debris out and grease in. Lastly, the assembly is closed with a method such as the pressed-in cover plate.

Many original equipment ball joints are designed as sealed units. If the protective boot fails, water and road debris will quickly cause wear and ball joint failure. Some aftermarket ball joints use an improved greasable design that allows lubrication to flush out contaminants to extend the life of the joints.

TOMOI Ball Joint Performance

TOMOI suspension ball head/external rod ball head series products Ball jacket adopts 40Cr fine forging standardized and hardened, 100% defect detection and then precision machining. The balance ball head series adopts Japanese high-precision automatic welding equipment, the welding angle is accurate, the impact strength and tensile force exceed 2000 kg.F, The ball casing material adopt slow carbon steel cold treatment process, unique forming, surface phosphate blackening, salt spray test for more than 72 hours. The ball stud is made of 40Cr material, the ball jacket is made of a Japanese special material, the ball head lubricant is made of Japanese special grease, the dust cover is made of Japanese Denka neoprene, the low temperature resistance reaches -45 degrees centigrade and the high temperature resistance reaches 120 degrees centigrade. Outstanding toughness and abrasion resistance.

■ Strong Surface Treatment

TOMOI has electro deposition coating comparable to the OE level to prevent rust from reducing durability.

■ Polymer Seat

TOMOI uses a polymer ball seat. Low friction damage and low variation in torque and clearance can keep performance long.

■ Hard & Soft Ball Stud

TOMOI reduces the surface roughness of the ball through the burnishing process, making the ball smooth.

■ It also has high strength by applying carbon steel, heat treatment, and cold forging.

Maintenance Tips:

Signs of damage to the vehicle ball joints are:

1.Knocking noise when the car drives over bumps

2.Creaking or squeaking noises when the suspension moves

3.Vehicle drifting to the side itself

4.The steering wheel feels loose or shaky

5.Premature tyres weathering

How To Check Ball Joints:

The primary way to check ball joints is to take your car on a test drive. You should keep the following bad ball joint symptoms in mind:

1.Are there unusual vibrations or noises coming from your vehicle? Make sure you have a keen eye to observe your car’s steering, turning, and handling feel.

2.Do you feel that the wheel is pulling to one side more? How would you rate your steering accuracy compared to normal days? Observe whether the steering wheel is in your complete control or if there is some more random movement?

3.Test the vehicle over bumpy roads more. Drive at high and low speeds to notice any out of normal vibrations or noises. Try driving at the speeding limit to observe changes, too.

4.After being done with the test drive, stop your vehicle and turn it from one side to the other. Is there any sort of popping or grinding sounds coming from the wheels?

Excellent TOMOI Ball Joint

TOMOI has more than 20 years experience in making of Steering and Suspension system. TOMOI Ball joints are manufactured with superior materials, innovative design, advanced equipment and high-end technology from Japan and Korea. TOMOI has passed the SGS-certified automotive industry quality management system lATF16949, strict performance tests (high and low temperature rotation resistance, mud spray and rubber dust protection test at high and low temperature, etc.) to ensure excellent and stable performance and durability of each product.