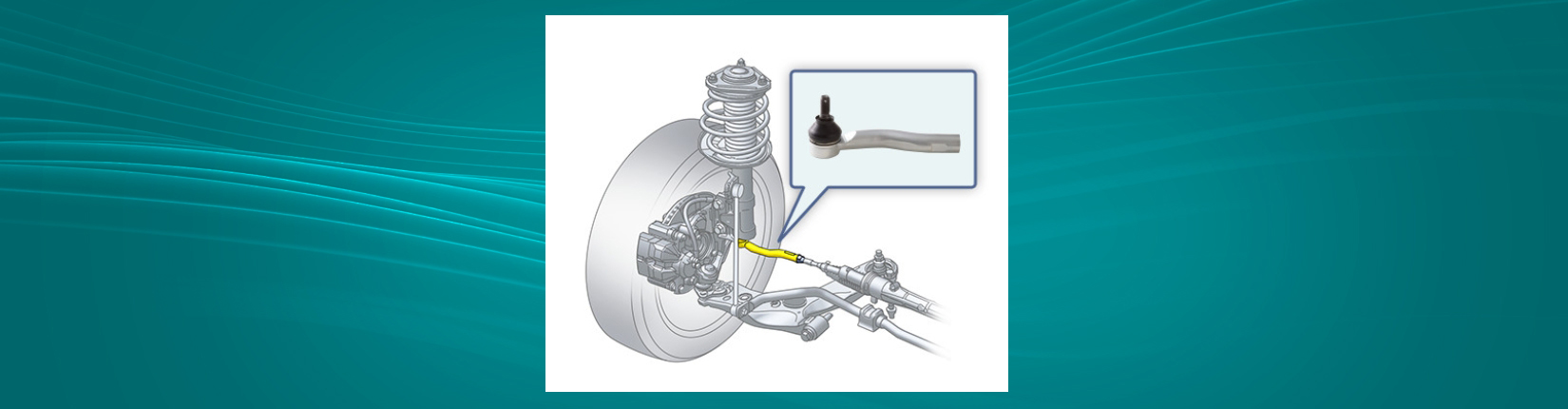

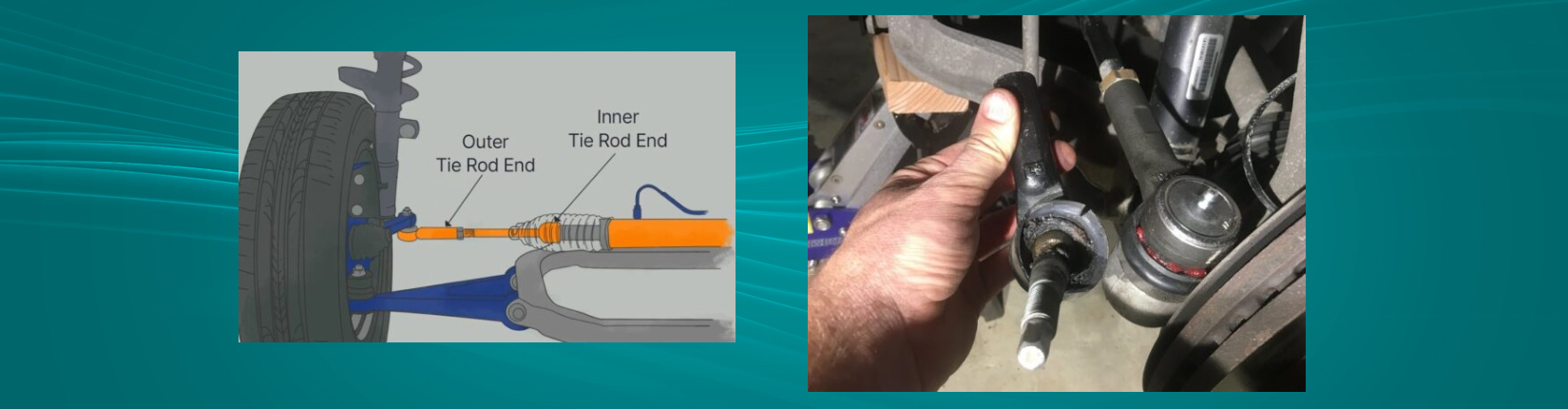

Tie Rod End,(indicates outer tie rod end) mechanically connects the knuckle and the rack end connected to the rack bar. The steering power input from the steering is transmitted to the tire so that the driver can move the vehicle in the desired direction. Tie rod end moves in accordance by the up-down movements of tires and transmits steering operations it receives from the steering side (rack end) to the tire side (knuckle end).

Tie Rod End Introduction

Tie rod end is the major part in vehicle steering system,the function is transmitting the steering power to the wheels,to control the wheels tracks and make the two wheel keep in simultaneous align the toe. Tie rod end is the major part in vehicle steering system. A tie rod end is a slender structural rod that is used as a tie and capable of carrying tensile loads. A tie rod end consists of an inner and an outer ends, it transmits force from the steering center link or the rack gear to the steering knuckle. This will cause the wheel to turn. The outer tie rod end connects with an adjusting sleeve, which allows the length of the tie rod to be adjustable. This adjustment is used to set a vehicle’s alignment angle. The function is transmitting the steering power to the wheels,to control the wheels tracks and make the two wheel keep in simultaneous align the toe.

TOMOI Tie Rod End Performance

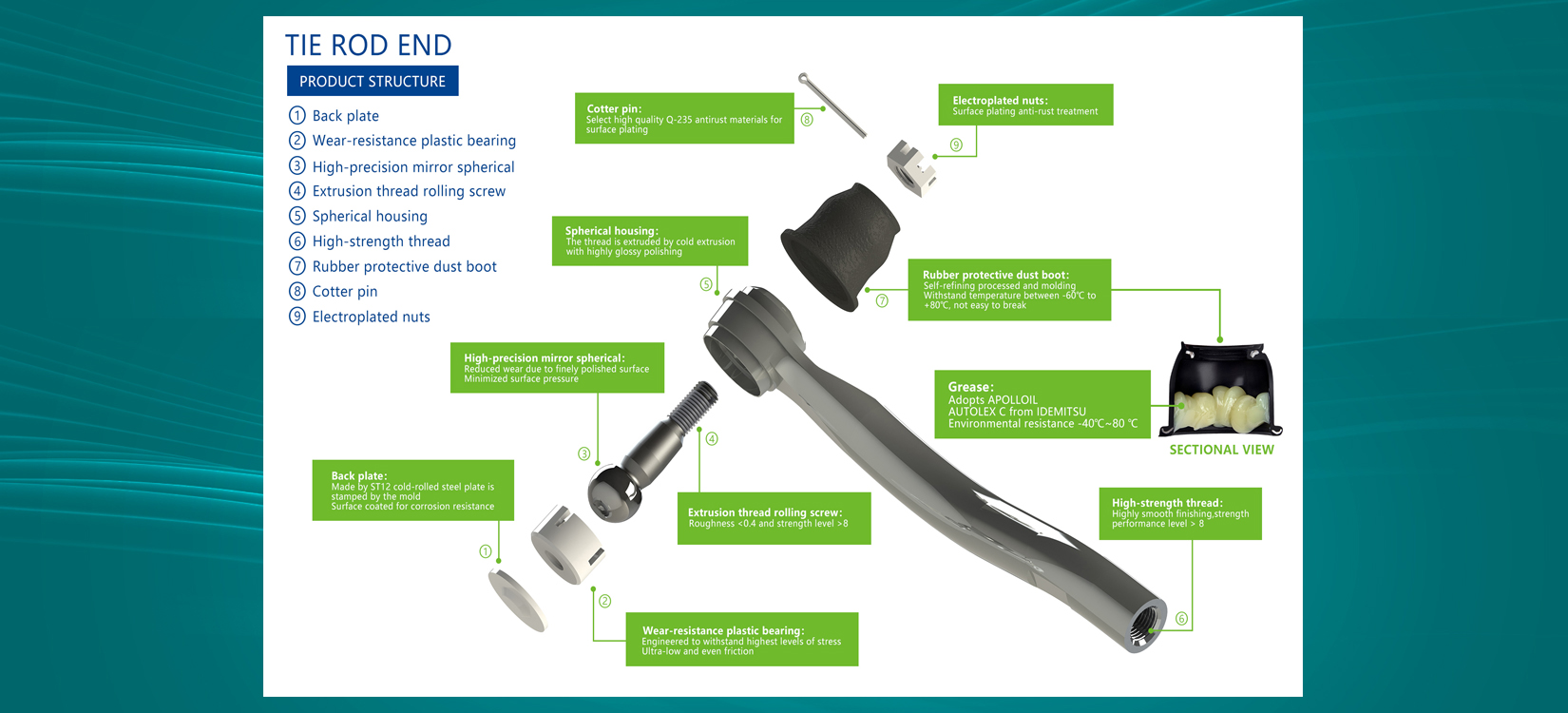

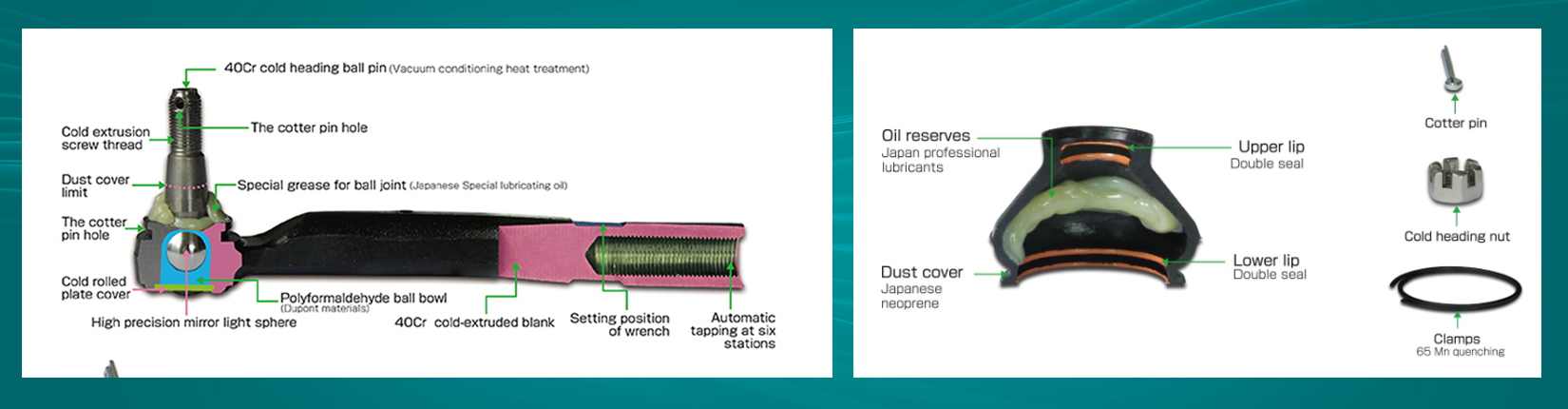

TOMOI suspension ball head/external rod ball head series products Ball jacket adopts 40Cr fine forging standardized and hardened, 100% defect detection and then precision machining. The balance ball head series adopts Japanese high-precision automatic welding equipment, the welding angle is accurate, the impact strength and tensile force exceed 2000 kg.F, The ball casing material adopt slow carbon steel cold treatment process, unique forming, surface phosphate blackening, salt spray test for more than 72 hours. The ball stud is made of 40Cr material, the ball jacket is made of a Japanese special material, the ball head lubricant is made of Japanese special grease, the dust cover is made of Japanese Denka neoprene, the low temperature resistance reaches -45 degrees centigrade and the high temperature resistance reaches 120 degrees centigrade. Outstanding toughness and abrasion resistance.

■ Strong Surface Treatment

TOMOI has electro deposition coating comparable to the OE level to prevent rust from reducing durability.

■ Polymer Seat

TOMOI uses a polymer ball seat. Low friction damage and low variation in torque and clearance can keep performance long.

■ Hard & Soft Ball Stud

TOMOI reduces the surface roughness of the ball through the burnishing process, making the ball smooth.

■ It also has high strength by applying carbon steel, heat treatment, and cold forging.

Maintenance Tips:

TOMOI advice your vehicle’s steering and suspension systems are checked regularly, at least once a year along with a complete wheel alignment. A worn tie rod can cause wandering, erratic steering and also major tire wear.

The most common problem with tie rod ends is when they wear out and get loose, which often happens when a rubber boot cracks or breaks and moisture penetrate inside the tie rod end causing corrosion. Outer tie rod ends fail more often. A loose tie rod is a major safety concern as it can separate. If a tie rod end separates, the vehicle will lose steering control.

Cautions:

■ Symptoms of a loose tie rod end include a clunking, rattling or knocking noise in the front end and looseness felt in the steering.

■ Excessively worn tie rod ends cause looseness in the steering. This might result in shaking in the front end that comes and goes at certain speeds.

■ Tie rods control steering angles. The tread or clamp connecting inner and outer tie rods is used to adjust steering angles, which means after the replacement of any of the tie rod ends, the vehicle will need the wheel alignment to bring the steering and suspension angles back to within specifications.

■ No need to replace both sides tie rod ends at the same time if a tie rod is in good shape.

However, tie rods on both sides wear out at the same rate. If one tie rod end is bad and the other is starting to go, it makes sense to replace both, so you won’t have to do the wheel alignment twice. Another reason to replace a working tie rod end is when the protective boot is damaged. Once the boot is damaged, the tie rod won’t last long.

■ In many modern cars, tie rod ends don’t need any maintenance as they are filled with grease and sealed at the factory. But in some cars, tie rod ends have grease fittings and must be greased periodically. You can check your owner’s manual or ask your mechanic to check if tie rods have grease fittings during a regular service.

At last, TOMOI Tie rod parts are constructed from strong forged steel for maximum the strength and durability. Choosing TOMOI products will ensure your driving safety.

Excellent TOMOI Tie Rod Ends

TOMOI has more than 20 years experience in making of Steering and Suspension system. TOMOI tie rod ends are manufactured with superior materials, innovative design, advanced equipment and high-end technology from Japan and Korea. TOMOI has passed the SGS-certified automotive industry quality management system lATF16949, strict performance tests (high and low temperature rotation resistance, mud spray and rubber dust protection test at high and low temperature, etc.) to ensure excellent and stable performance and durability of each product.