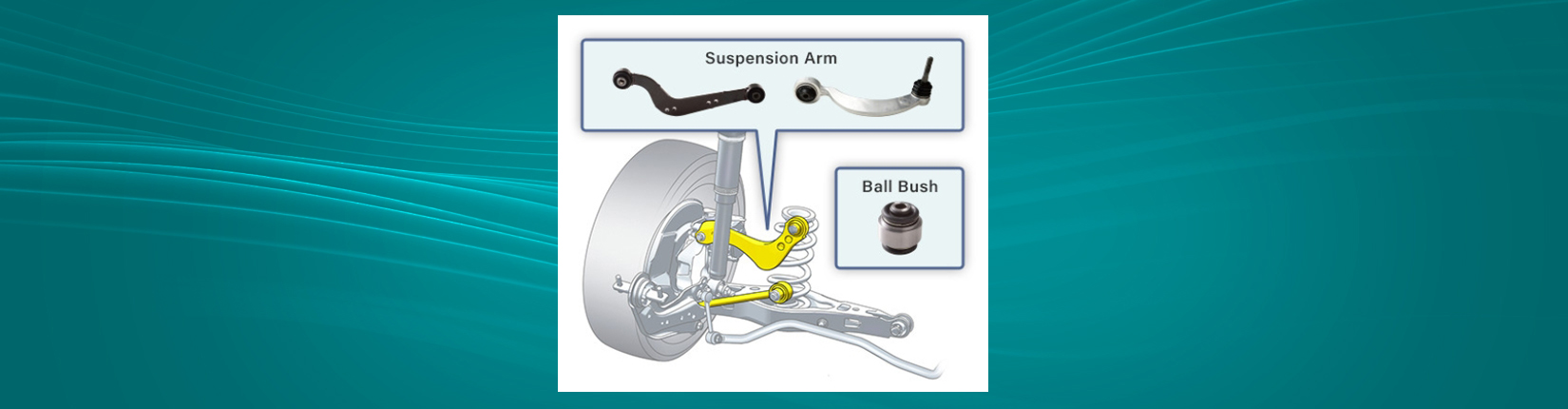

Suspension Arm links between the tire side (Wheel carrier) and the body, and maintains the tires always in the ideal position. Suspension Arm Ball Bush, it serves the same purpose as ball joints but is used in the rear section. The bushing pressed into the control arm prevents vibration and noise at the connection between the control arm and the vehicle frame. The thick rubber bushing balances elasticity and rigidity for a comfortable ride and excellent durability.

Bushing Introduction

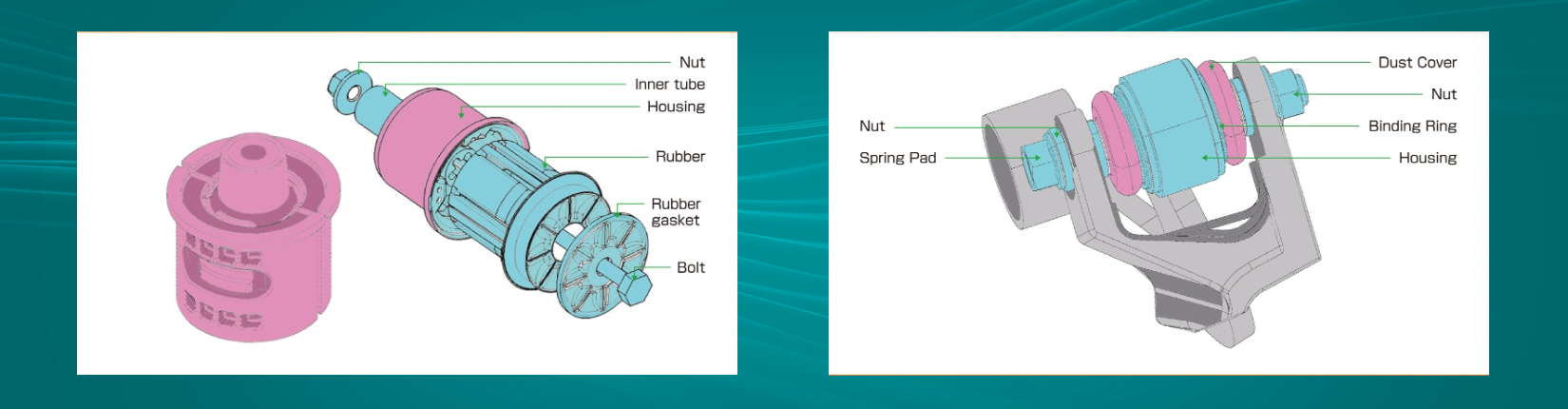

The chassis suspension of the car will vibrate when driving. Usually, bushings will be installed on the control arm and balance bar to avoid mutual motion interference between the parts of the suspension while shaking and vibrating, as well as to avoid external impacts and vibrations, thereby contributing to a protective effect and enhancing driving comfort.

Bushings are both resilient and damped, storing energy as springs do and releasing that energy, while absorbing energy as shock absorbers do. Multiple bushings are available in the suspension control arm, with each having a distinct performance impact on the vehicle.

1.The front bushing is primarily to guarantee the performance of the front suspension system in terms of smoothness of the car, thus its stiffness is relatively small; the rear bushing is primarily to guarantee the performance of the rear suspension system in terms of handing stability of the car, thus its stiffness is rather large.

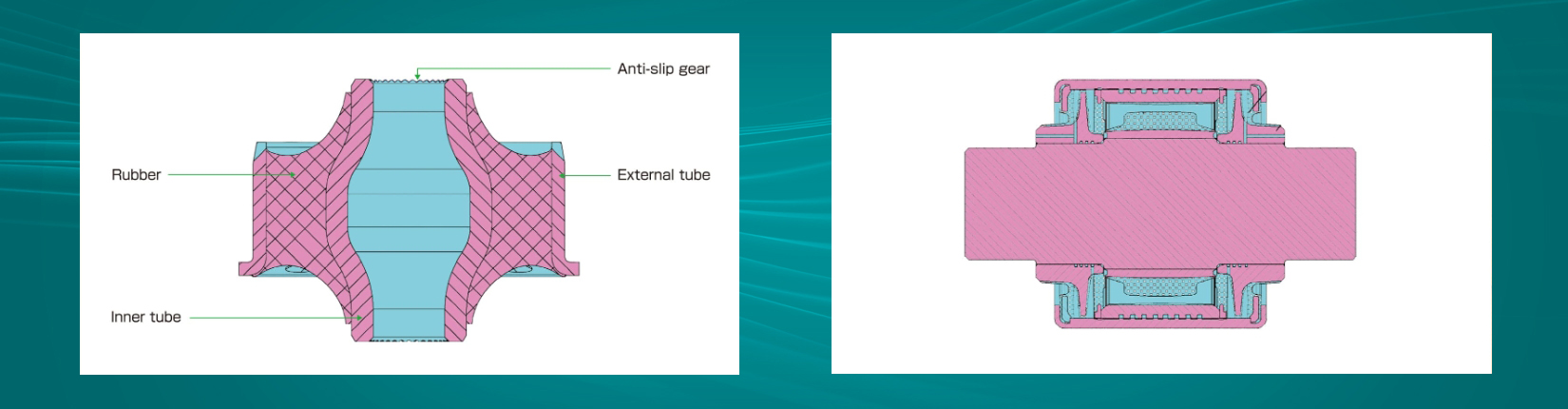

2.Typical rubber metal bushing structure, as compared to rubber bushings consisting of regular cylindrical shaped metal tubes (conventional rubber bushings), the bushings have less tapered swing stiffness; with greater radial stiffness and lower axial stiffness.

Bushing Structural Diagram

TOMOI Bushing Strengths

1.Adopting high-grade natural Thai rubber, which features excellent elasticity, oil resistance, acid resistance, corrosion resistance, etc., and high tensile strength, which significantly extends the service life of the bushing.

2.Using 20# or 35# steel, which is solid and durable.

3.Using HF INTERMlXX engagement type refining technology for highly dispersible and temperature sensitive rubber products, which makes the service life and comfort of the rubber in the bushings much better.

4.Adopting German rubber injection machine/DESMA rubber products vulcanization equipment with stable temperature control, intelligent monitoring of the production process and records of products.

5.Adopting American MTS elastomer testing/ static and dynamic stiffness testing equipment. 6.Using Japanese Zeiss ZElSS metallic microscope (analytical grade) metal material tester.

7.Conducting product testing using testing equipment such as rubber constant temperature and humidity, thermal calibration, high and low temperature, and ozone calibration chamber.

8. The products comply with the following standards. SAEJ1401/FMVSS106/GMW3056

Maintenance Tips

Inspecting regularly whether the rubber bushings of swing arms and tie rods are cracked or become loose

Tires will oscillate abnormally when the car is moving and the tires will wear out improperly when the bushings are damaged

The chassis will have abnormal sound generated.

When to replace the bushings?

The state of the bushing will have a direct impact on the comfort of driving, also the bushing belongs to the delicate and wearable parts.

then when do we should replace the bushing?

■ Perceiving whether the wheels have any abnormal phenomenon such as irregular shaking and response.

■ Identifying the surface condition of the bushing, whether there are cracks and breakage. A serious cracking and ripping would be a sign hat the bushing has run out of life, Occasionally there are some fine cracks that we see on the rubber surface of the bushing which appear to be very compact and shallow. it may not affect its function much at this time, however, this has been a warning that the rubber is aging and needs to be changed.