Symptoms of Bad Tie Rod Ends And How To Replace Them

Symptoms of Bad Tie Rod Ends And How To Replace Them

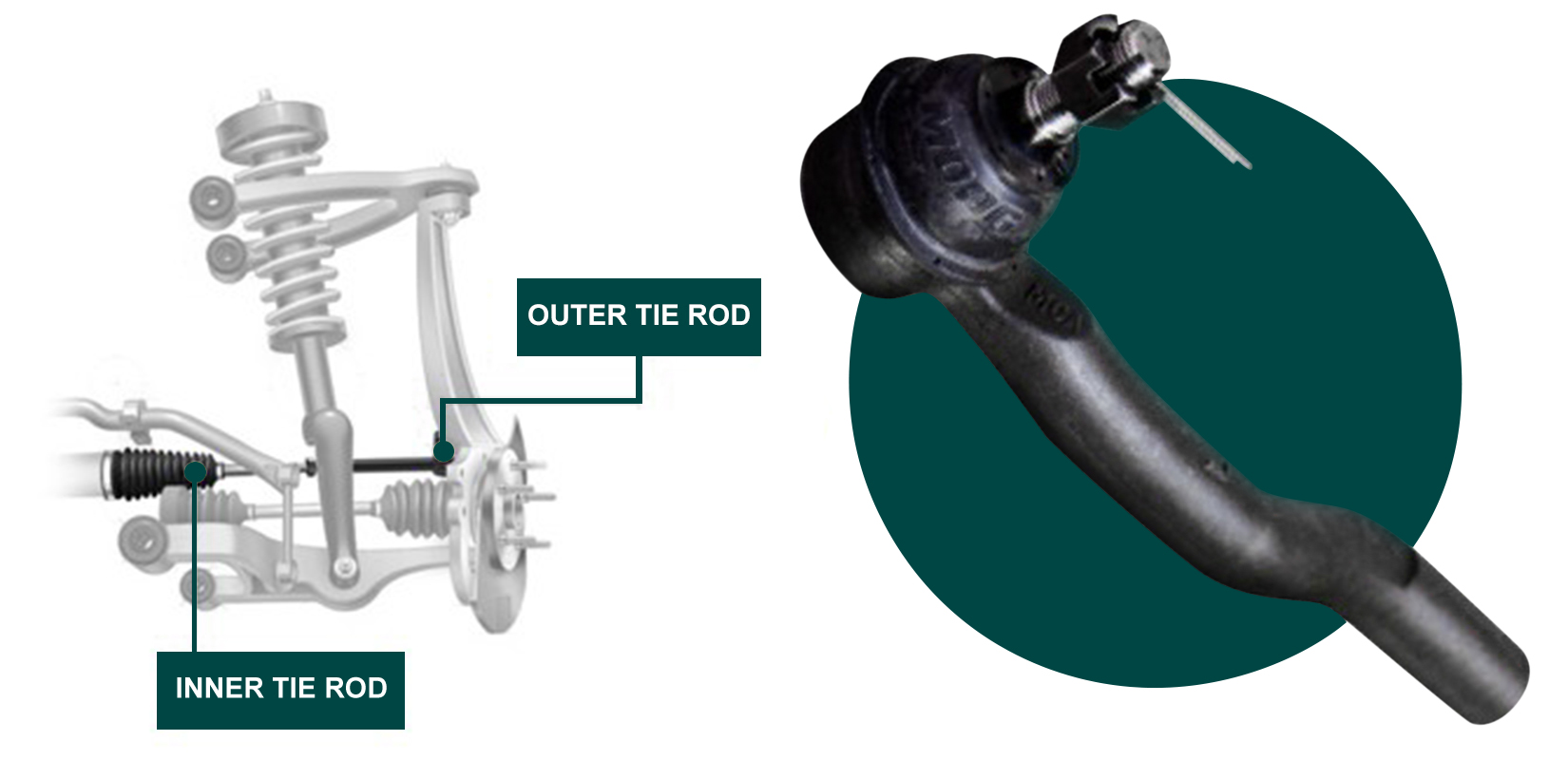

What Is a Tie Rod?

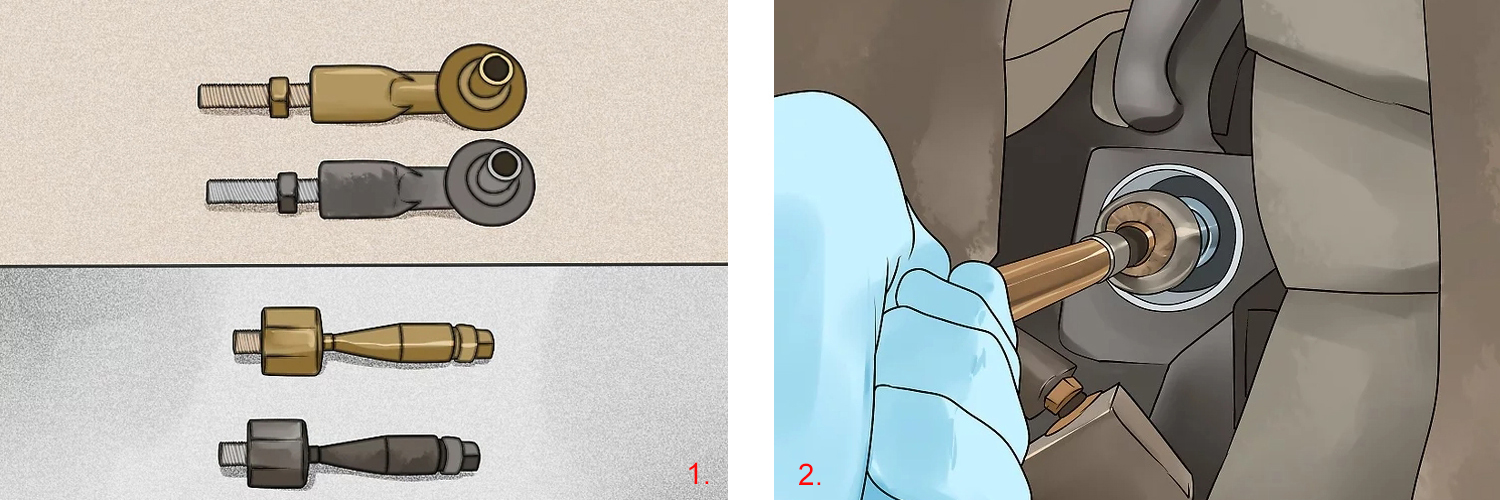

A tie rod is a mechanical part that connects your steering gear to your steering knuckle. They consist of two parts, inner and outer ends, that are connected and can be adjusted at the middle. Each end has a ball joint, so each tie rod has two ball joints. Each tie rod has two ends, one inner and one outer. The inner tie rod end connects to the steering, while the outer tie rod end connects to the steering knuckle.

Symptoms of a Bad Tie Rod End

Here are a few symptoms you may be experiencing.

1. Uneven Tire Wear

Inspect the tread of your tires for signs of irregular tire wear, especially on the inner and outer edges. Irregular tire wear could be a sign of loose tie rods that need to be checked prior to doing an alignment.

2. Knocking or Clunking Sounds

If you notice strange noises when turning or driving along a bumpy road, you may have damaged tie rod ends.

3. Excessive Looseness in Steering Wheel

Looseness in the steering wheel could indicate worn-out tie rods.

4. Visible Damage

Regularly check your steering rods for signs of wear. Any noticeable issues should warrant a closer examination.

5. Difficulty Steering

A sure sign that it’s time to replace your tie rods is the inability or challenges in steering, especially at high speeds. This is dangerous because you can easily lose control of your vehicle.

Should tie rod ends be replaced on both sides at the same time?

No, If a tie rod is in good shape, there is no need to replace it. Often, however, tie rods on both sides wear out at the same rate. If one tie rod end is bad and the other is starting to go, it makes sense to replace both, so you won’t have to do the wheel alignment twice. Another reason to replace a working tie rod end is when the protective boot is damaged. Once the boot is damaged, the tie rod won’t last long.

Should both inner and outer tie rod ends be replaced together? Again, there is no need to replace the part if it’s good.Does a tire rod need any maintenance? In some cars and trucks, tie rod ends have grease fittings and must be greased periodically. In many modern cars, tie rod ends don’t need any maintenance as they are filled with grease and sealed at the factory. You can check your owner’s manual or ask your mechanic to check if tie rods have grease fittings during a regular service.

How to replace tie rod ends?

Replacing tie rod ends refers to repairing an integral part of a vehicle’s steering mechanism. With a few basic tools and a little bit of know-how, this is a procedure that anyone, with a little bit of automotive experience, can perform on their own.

Quick Tie Rod End Replacement Guide:

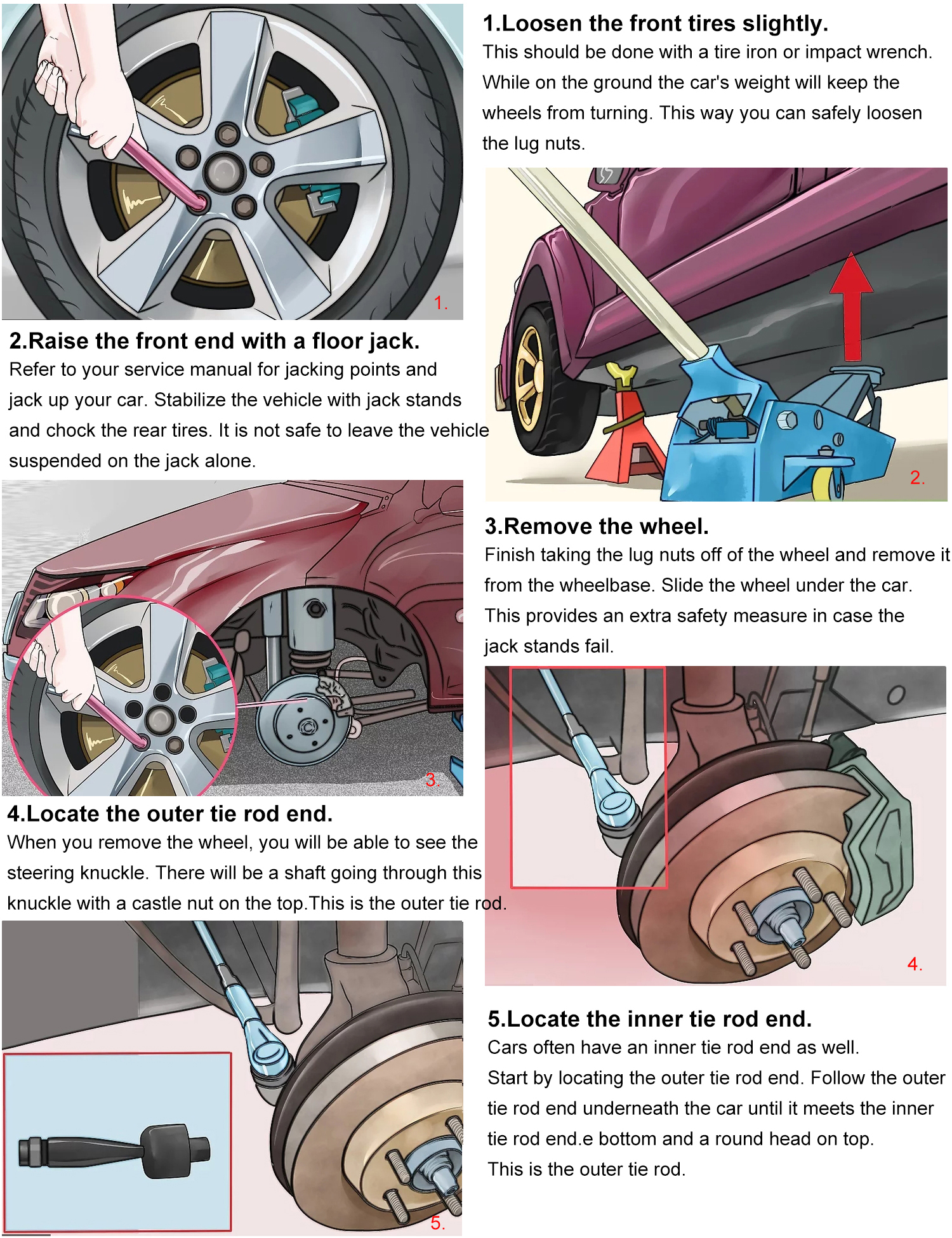

■ Remove the wheel by loosening the tire and jacking up the front of the car, then locate both tie rod ends on the wheel.

■ Loosen the pinch nut with a wrench and move it to touch the outer tie rod end. Then remove the cotter pin and castle nut.

■ Remove both tie rod ends and replace them with new tie rod ends. Repeat the process in reverse to put the wheel back on.

Part 1: Accessing the Tie Rod End

Part 2: Removing the Tie Rod End

Part 2: Removing the Tie Rod End

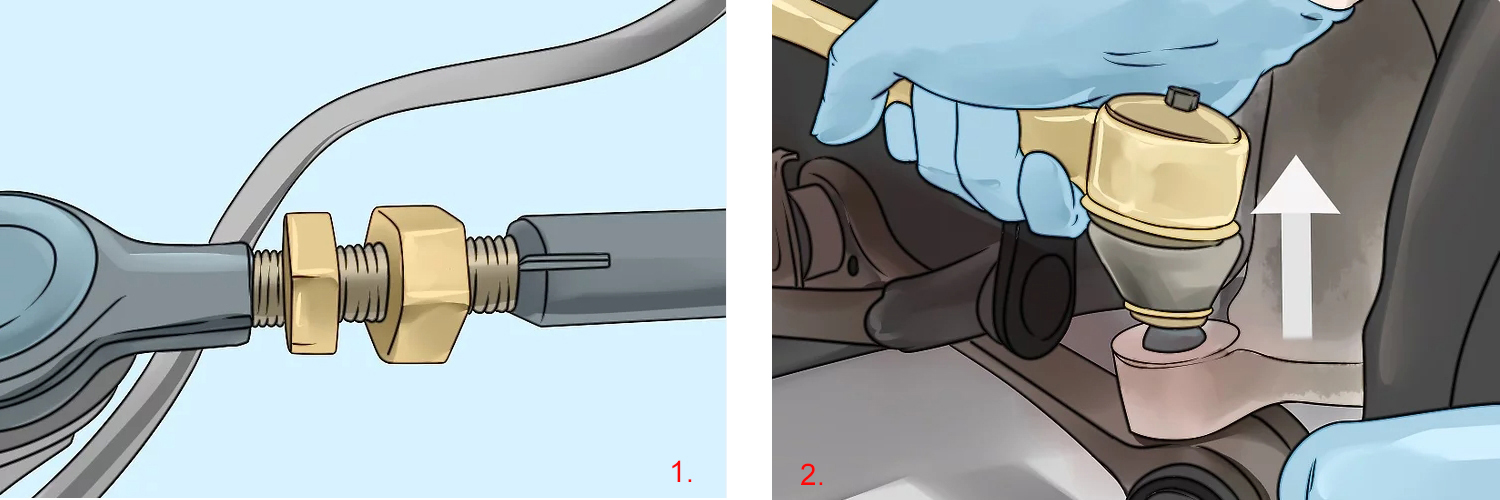

1.Use a wrench to loosen pinch nut. This nut holds the outer tie rod end in place and prevents it from moving along the spindle of the inner tie rod end. Loosening it will allow you to twist the outer tie rod end. By design, the outer tie rod end must be twisted off from the inner tie rod end.

2.Move the pinch nut up to touch the outer tie rod end. This will mark the location of your outer tie rod end and you will know how far to thread on the replacement. Do not tighten the pinch nut. If you do, you will not be able to easily turn the outer tie rod end.

3.Remove the cotter pin. This pin will be located where the tie rod end meets the steering knuckle. Use a pair of needle nose pliers to straighten out the pin and then pull it out. Throw the cotter pin away. It should not be reused.

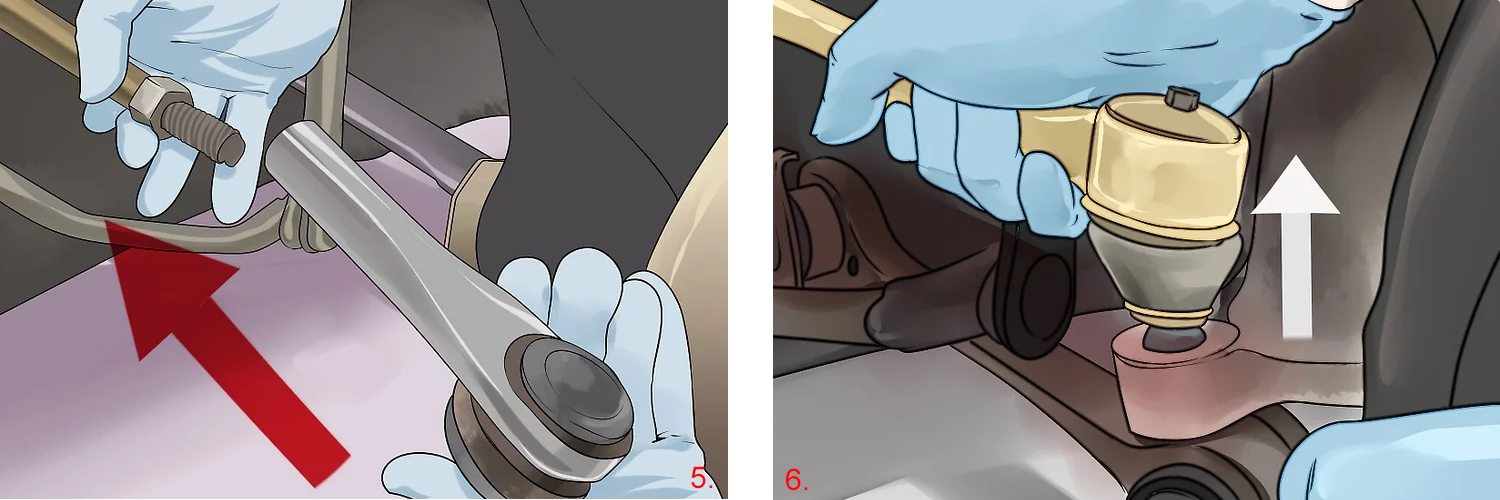

4.Use a properly sized ratchet to remove the castle nut. This is the nut that the cotter pin went through. It holds the tie rod end to the steering knuckle. Removing it will allow you to remove the outer tie rod end.

4.Use a properly sized ratchet to remove the castle nut. This is the nut that the cotter pin went through. It holds the tie rod end to the steering knuckle. Removing it will allow you to remove the outer tie rod end.

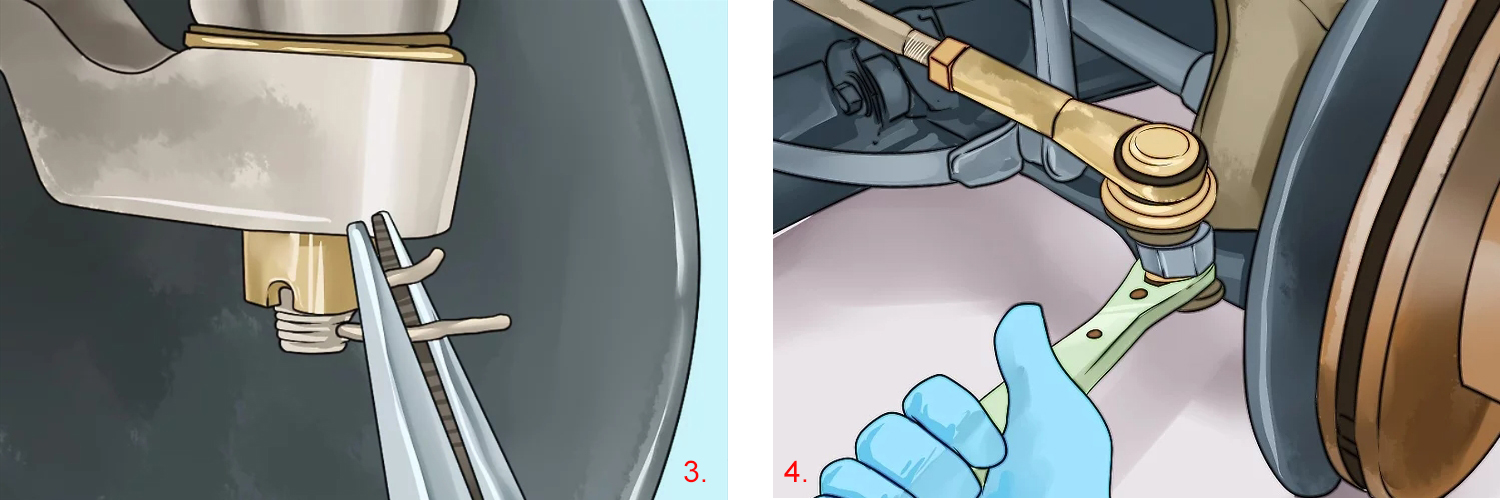

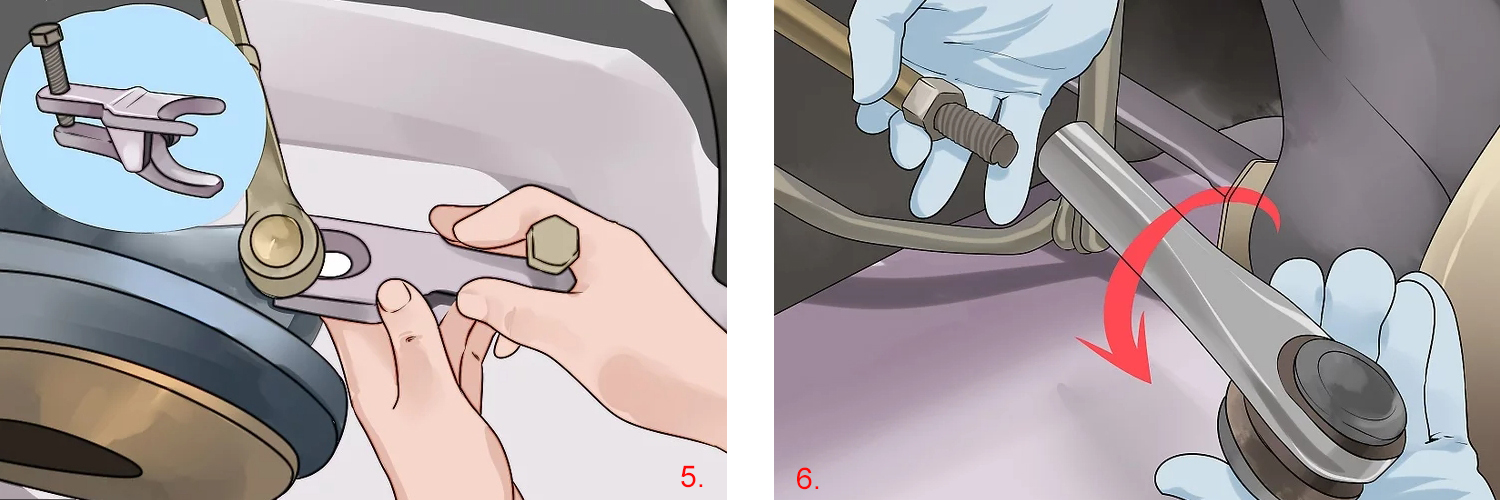

5.Remove the outer tie rod end from the steering knuckle. To do this, you can use a tie rod puller or a ball joint separator.

■ Insert the tool between the ball joint of the outer tie rod end and the steering knuckle.

■ Use it to pry the shaft out of the steering knuckle.

6.Remove the outer tie rod end from the inner tie rod end. To do this, you will twist the outer tie rod end off of the spindle of the inner tie rod end. Turn it counterclockwise to loosen. Remember to count exactly how many turns it takes you so that you can tighten the replacement the same number of turns. This helps keep your alignment as close as possible.

6.Remove the outer tie rod end from the inner tie rod end. To do this, you will twist the outer tie rod end off of the spindle of the inner tie rod end. Turn it counterclockwise to loosen. Remember to count exactly how many turns it takes you so that you can tighten the replacement the same number of turns. This helps keep your alignment as close as possible.

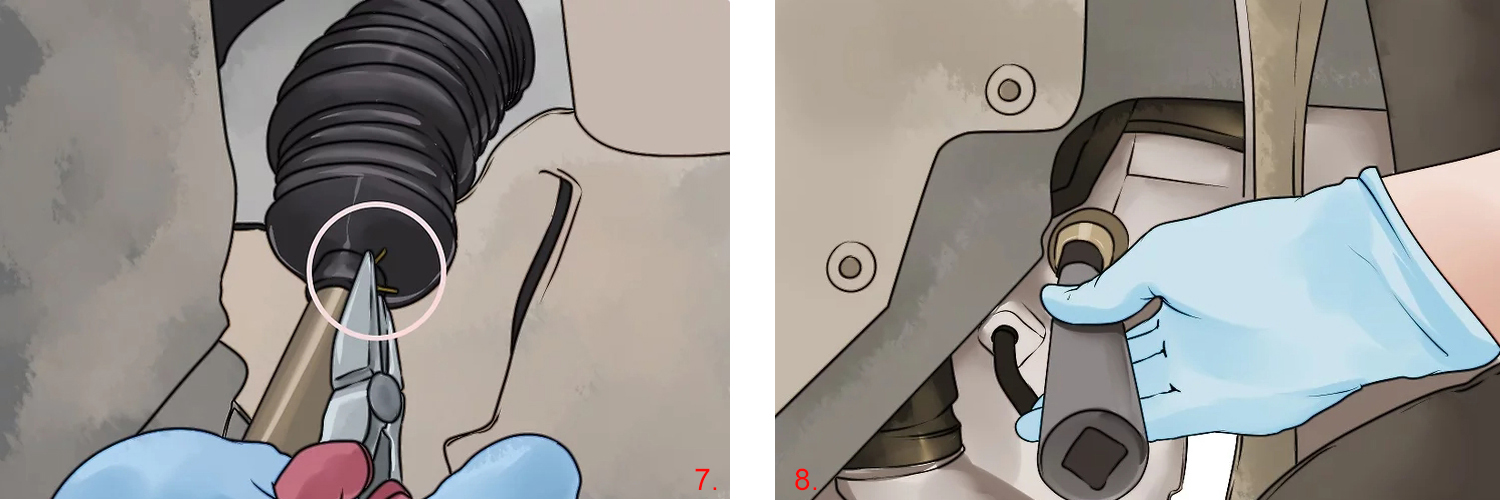

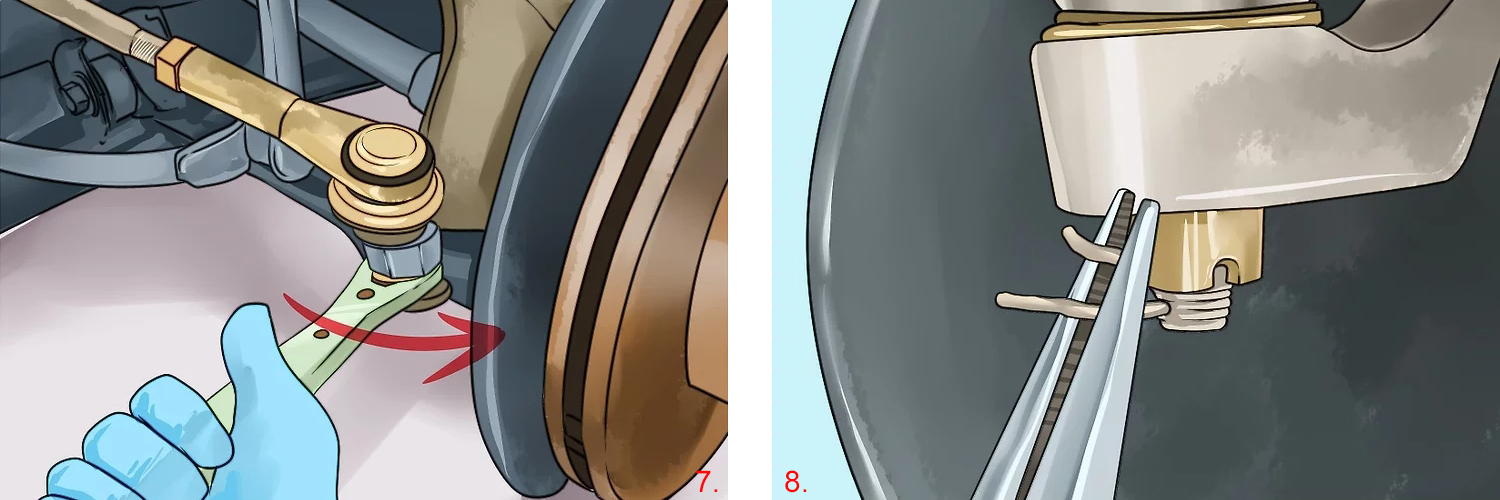

7.Remove the boot from the inner tie rod end. Only do this if you are replacing both inner and outer tie rod ends. You will need to remove the pinch nut. Next, take a pair of pliers and remove the clamp from the boot on the inside end of the inner tie rod end. There is another clip on the far side of the boot that you will have to break with a flat head screwdriver. Insert the screwdriver and twist to break it. Now you can slide the boot off.

8.Remove the inner tie rod end. Some cars have a small pin that will need to be removed before the rod end can be turned. Locate the pin and with a flathead screwdriver pry the pin out. You might need to give the flathead a few taps with a hammer to get it started. Once the pin has been removed you can remove the tie rod end. To do this, you will need a large, deep socket that fits over the inner tie rod end. There is also a tie rod removal tool that will make the job much easier that can you can use from any part store that does the loan a tool program. Twist the inner tie rod end counterclockwise until it is loose. Pull it off of the car.

■ If you can gain access to the inner tie rod end, this can possibly be done with a wrench, if necessary.

■ You can get an adaptor that fits over the inner tie rod end and makes it easier to fit a socket onto the inner tie rod.

Part 3: Replacing the Tie Rod End

1.Check to make sure your new tie rod end is comparable to the old one. If there is any doubt that the new tie rod end is compatible with your vehicle, do not use it until you consult a mechanic. They should be approximately the same shape and size. If they are exactly the same length that is even better.

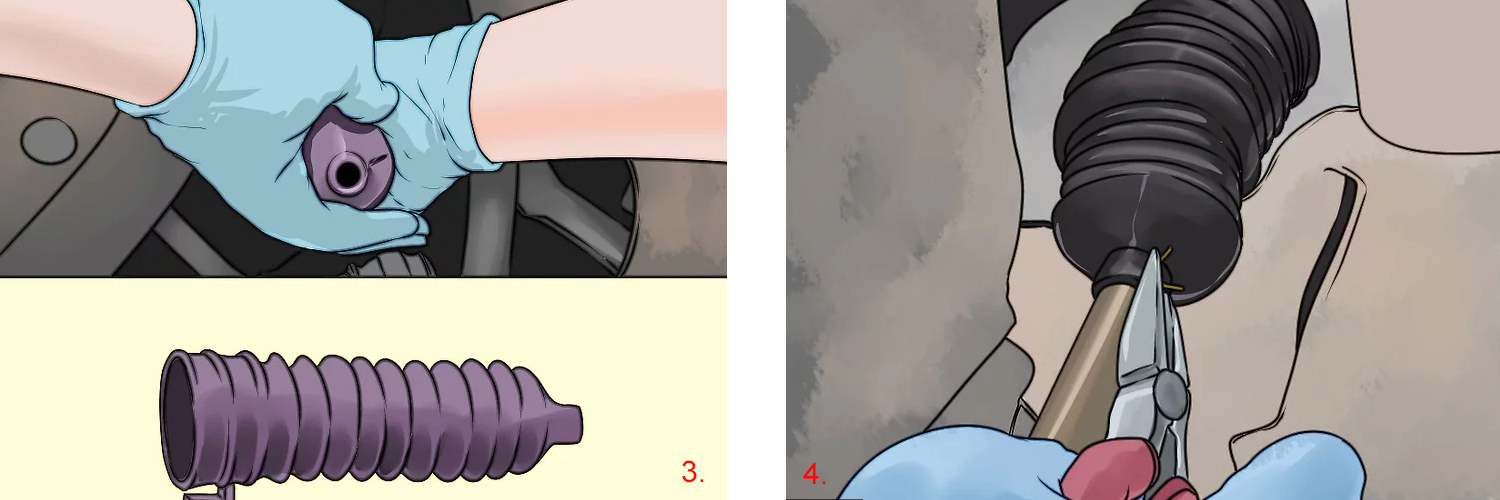

2.Thread the new inner tie rod end into the steering gear. This should be done with the same socket or wrench as before. However, you do need to check your owner’s manual or service manual to find the proper torque value. Use a torque wrench to ensure that you twist the inner tie rod end to the correct torque values.

2.Thread the new inner tie rod end into the steering gear. This should be done with the same socket or wrench as before. However, you do need to check your owner’s manual or service manual to find the proper torque value. Use a torque wrench to ensure that you twist the inner tie rod end to the correct torque values.

3.Slide the boot back onto the inner tie rod. You will have to replace the clip that you broke, as they are a one time use only. It is ideal to have one before you start the job. Once you slide the boot up the inner tie rod end and into place, fasten the new clip. Then use the pliers to refasten the second clip on the boot.

There is a vent port on the boot that must be lined up with a tube on the steering gear.

4.Thread the pinch nut back on. This must be done before you try to put the outer tie rod end on. Take the pinch nut far enough up the shaft so that it will not interfere with the outer tie rod end being put on.

4.Thread the pinch nut back on. This must be done before you try to put the outer tie rod end on. Take the pinch nut far enough up the shaft so that it will not interfere with the outer tie rod end being put on.

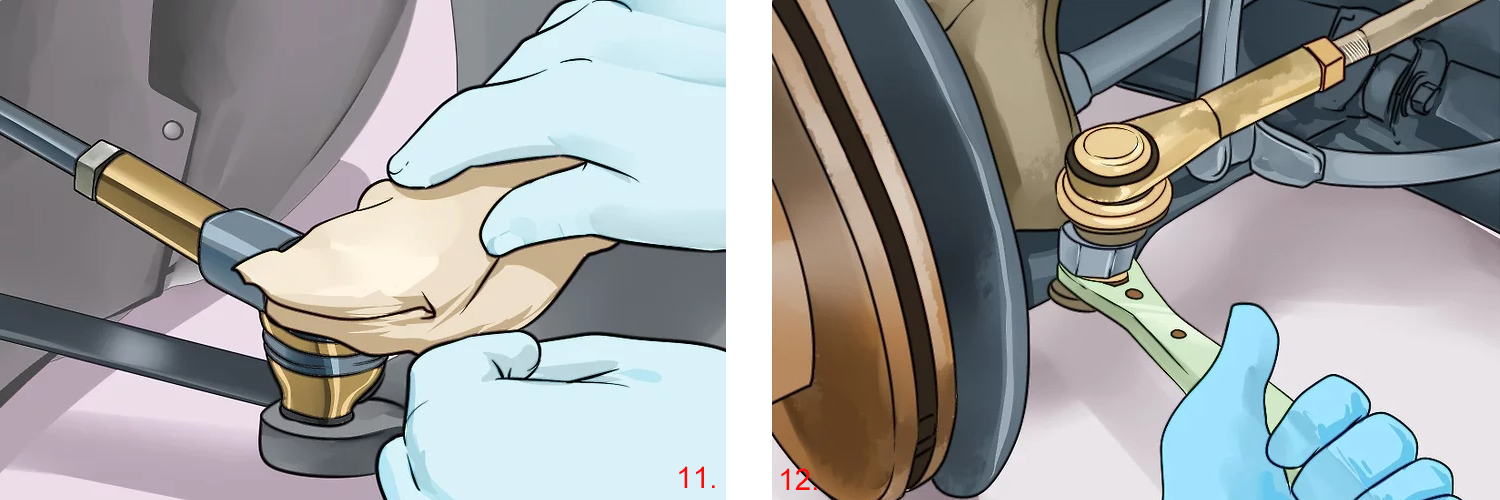

5.Thread the new outer tie rod end onto the inner tie rod shaft. You should thread it by hand exactly the same number of turns that it took to take it off. Then thread the pinch nut up to the outer tie rod end. Tighten the pinch nut to keep the outer tie rod end from moving.

6.Connect the tie rod end to the steering knuckle. The shaft of the tie rod end will fit down through the knuckle just as the old tie rod end did. You can move the knuckle and the tie rod end as needed to get them to align properly.

6.Connect the tie rod end to the steering knuckle. The shaft of the tie rod end will fit down through the knuckle just as the old tie rod end did. You can move the knuckle and the tie rod end as needed to get them to align properly.

7.Tighten the castle nut. This will secure the tie rod end to the steering knuckle. Check your owner’s manual or service manual for exact torque specifications for this bolt.

8.Replace the cotter pin. Make sure that the castle nut aligns with the hole in the tie rod end shaft. Slide the cotter pin through the hole and bend the ends back to wrap it around the castle nut. This prevents driving vibrations from loosening the castle nut. Always be sure to install a new cotter pin. Do not reuse the old pen.

8.Replace the cotter pin. Make sure that the castle nut aligns with the hole in the tie rod end shaft. Slide the cotter pin through the hole and bend the ends back to wrap it around the castle nut. This prevents driving vibrations from loosening the castle nut. Always be sure to install a new cotter pin. Do not reuse the old pen.

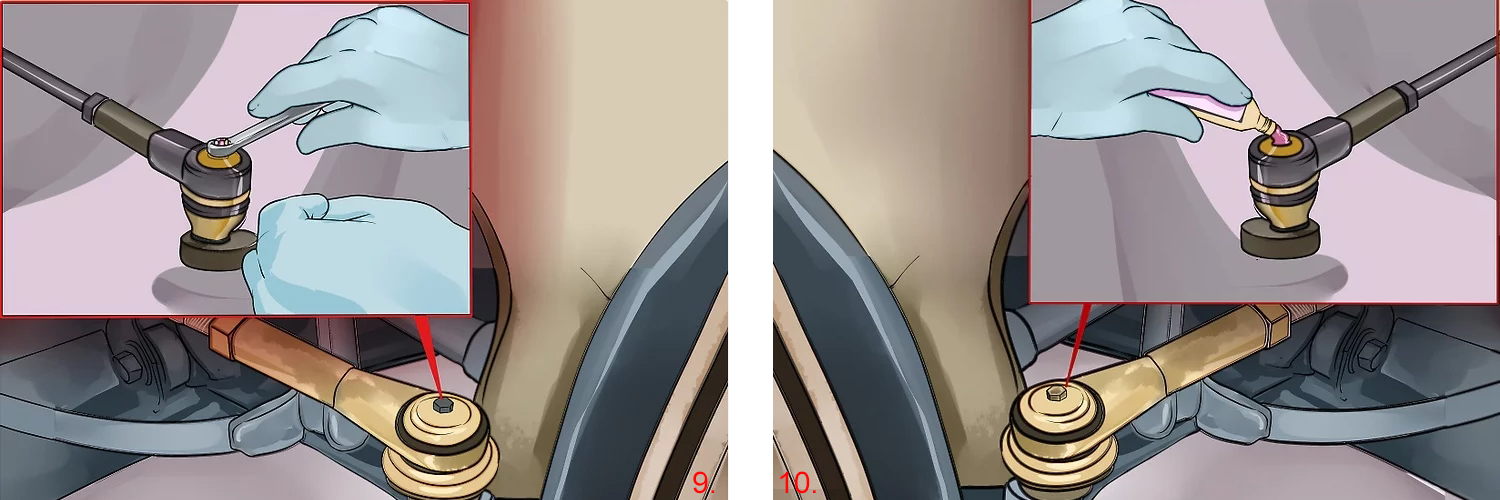

9.Install the grease fitting on the tie rod end. Some tie rod ends come with a grease fitting that simply screws into the top of the tie rod end. If this is the case for you, install it now.

10.Apply grease to the tie rod end assembly generously. This is only necessary if your tie rod ends come with a grease fitting. Apply grease until it is visible on the outside of the tie rod end with a grease gun. You should put use enough grease that you see it on the outside of the tie rod end.

10.Apply grease to the tie rod end assembly generously. This is only necessary if your tie rod ends come with a grease fitting. Apply grease until it is visible on the outside of the tie rod end with a grease gun. You should put use enough grease that you see it on the outside of the tie rod end.

11.Clean up the excess grease. This will prevent damage to the brakes and rotors.

12.Tighten the pinch nut. Use an open end wrench to tighten the pinch nut as tight as you can against the tie rod end. This will ensure that your vehicle is as close as possible to being back in alignment.

12.Tighten the pinch nut. Use an open end wrench to tighten the pinch nut as tight as you can against the tie rod end. This will ensure that your vehicle is as close as possible to being back in alignment.

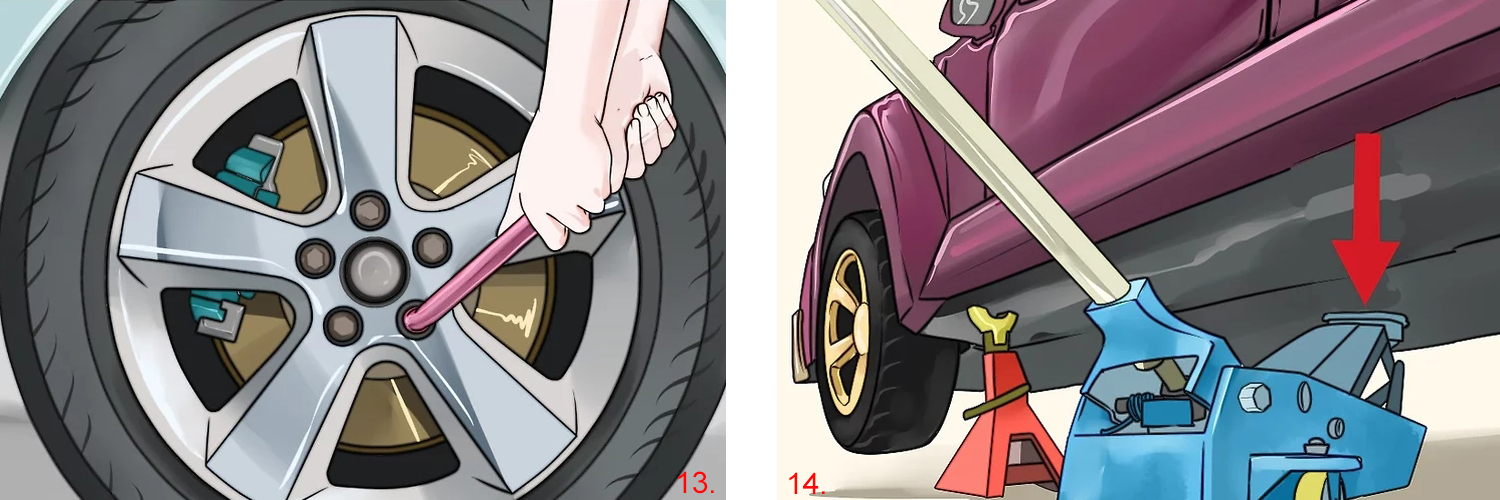

13.Replace the wheel. Tighten the lugs by hand in a star pattern.

14.Lower the vehicle to the ground. Use the floor jack to lift the car off of the jack stands and then lower it to the ground slowly.

14.Lower the vehicle to the ground. Use the floor jack to lift the car off of the jack stands and then lower it to the ground slowly.

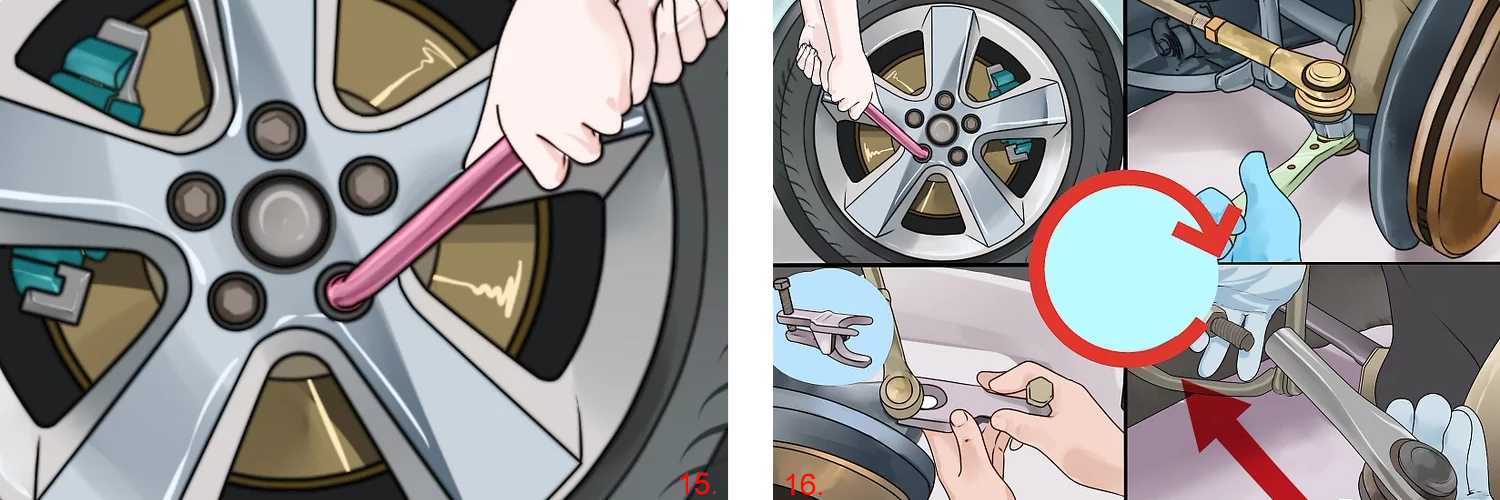

15.Tighten the lug nuts. Use a lug wrench or impact to tighten the lug nuts to the specified torque. Again, tighten in a star pattern.

16.Repeat this process to install the tie rod ends on the other side. If you need to replace both sides, the process is the same.

16.Repeat this process to install the tie rod ends on the other side. If you need to replace both sides, the process is the same.

17.Get a front end alignment. Now that you have altered parts steering system, you will need to have your front end aligned by a professional to avoid uneven wear and tear.

Community Q&A

1.Should I put a pin back in the inner tie rod where it bolts onto the rack and pinion on a 2008 Ford Mustang GT?

-Inner tie rods thread on to the rack and do not use a castle nut or cotter pin, they thread on to the rack, and make sure to use RED loctite. They use a washer that you need to bend in so if the tie rod backs off, the washer acts as a safety. The outer tie rod uses a castle nut with a cotter pin; if you are tightening the nut, do not back it off to put the cotter pin in, always tighten to get it in so the taper between the tie rod and the knuckles steering arm is not loose.

1.Are the tie rods the same length on both sides?

-Not that I’ve seen. Look up the part numbers for the right and left side outer tie rod ends to verify. If they are different part numbers, they are not the same.

1.Do I install a tie rod end top or bottom on with the castle nut?

-Yes, you need to make sure your threads on the top of the nut are the same as the ones on the other nuts.